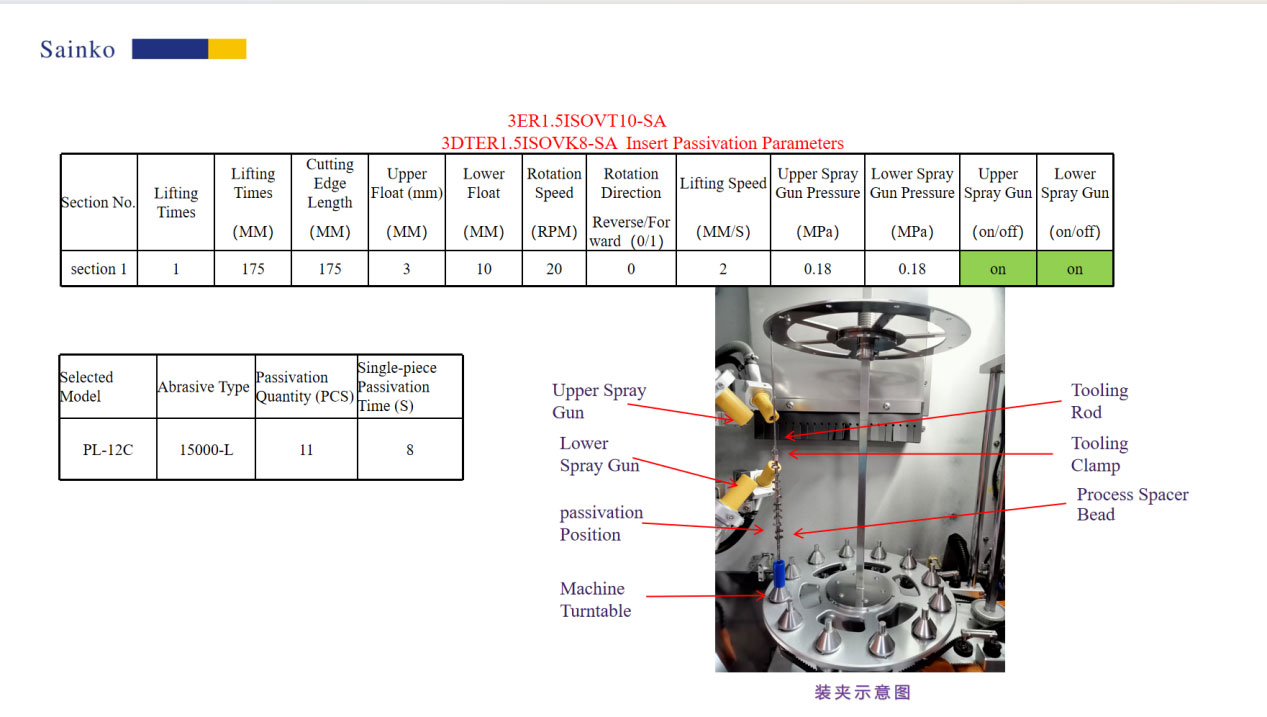

This passivation verification was conducted on two types of inserts. The customer requirement was to achieve the preset target edge radius through passivation, improve cutting edge defects, and enhance cutting performance.

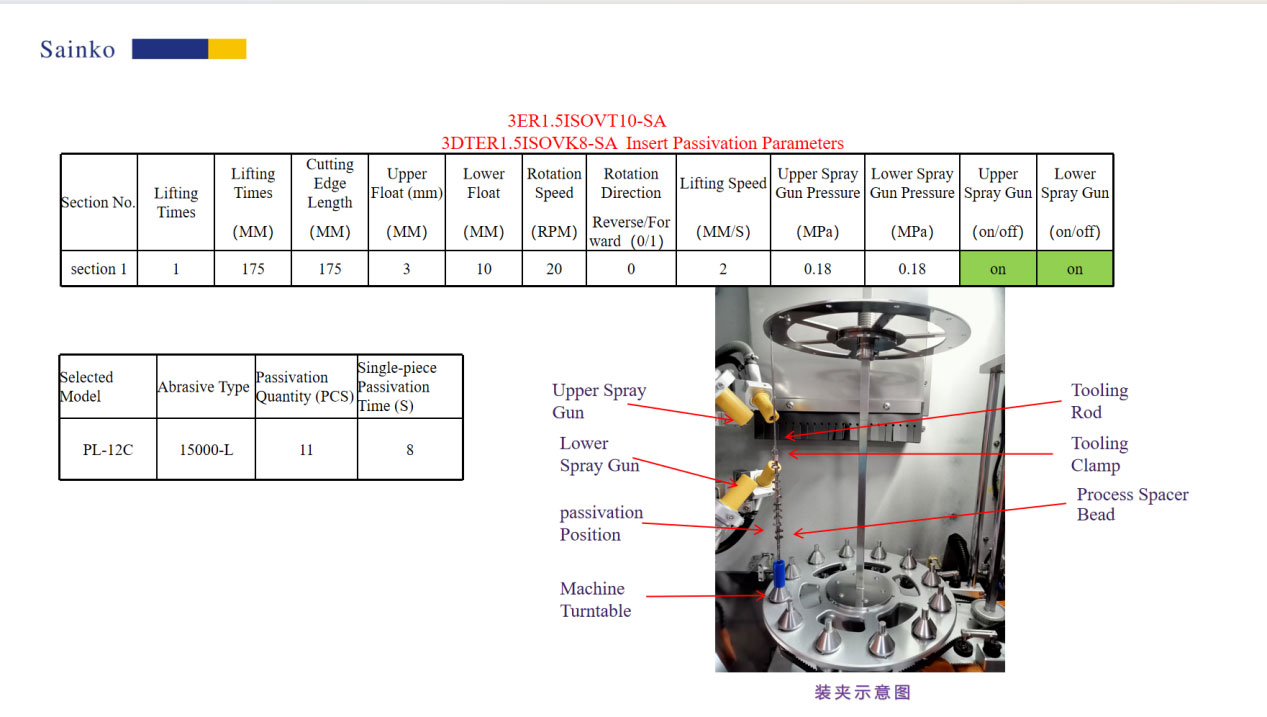

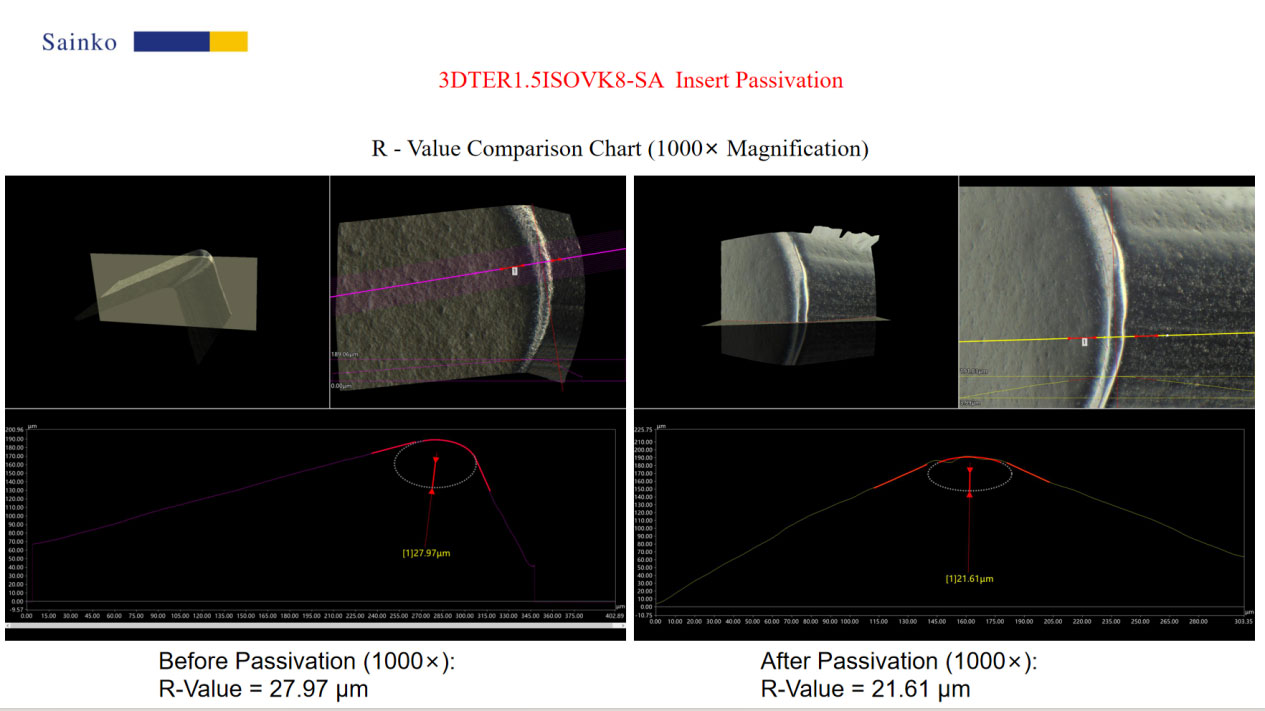

The verification was performed using a PL-12C tool passivation and polishing machine with 15000-L abrasive. Detailed parameters are shown in the attached figure.

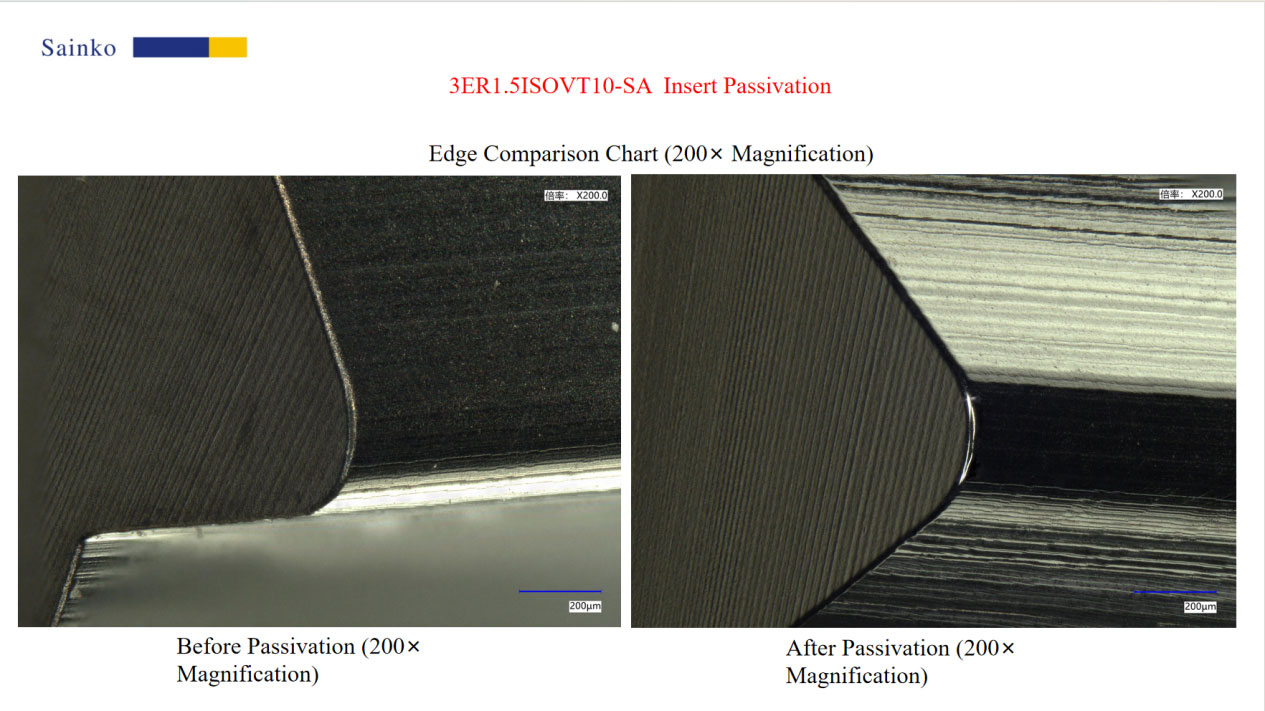

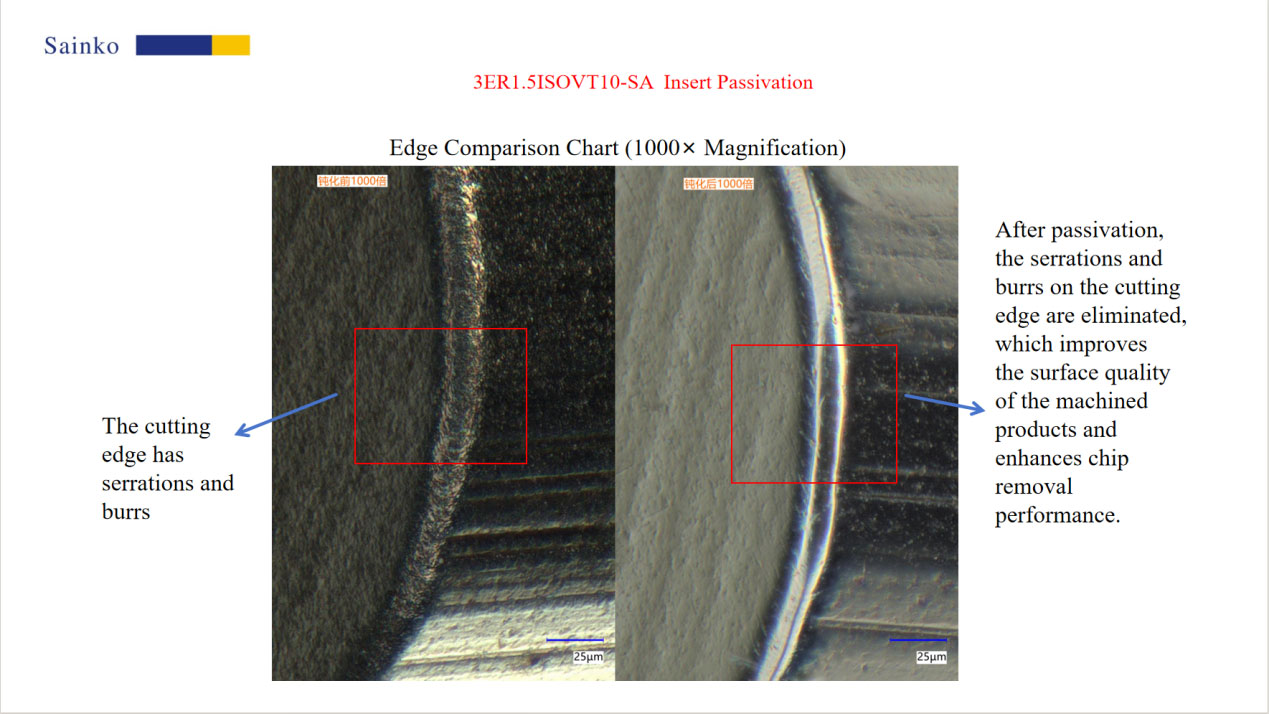

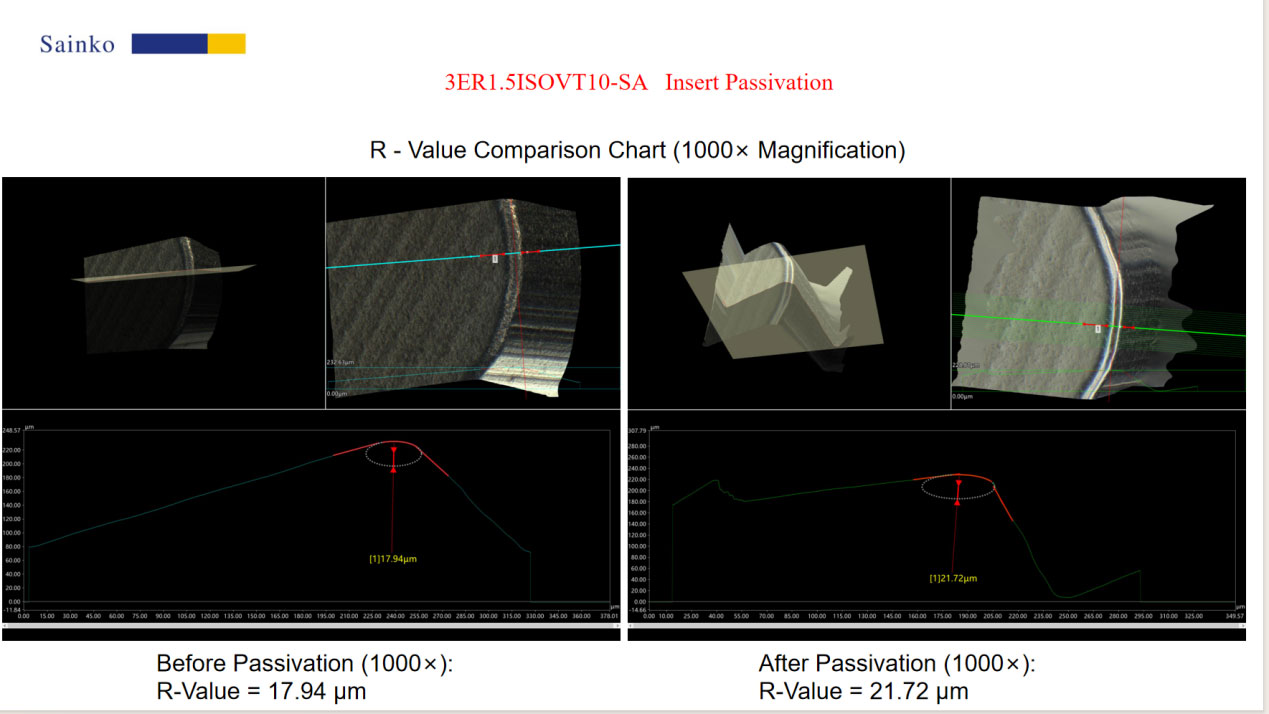

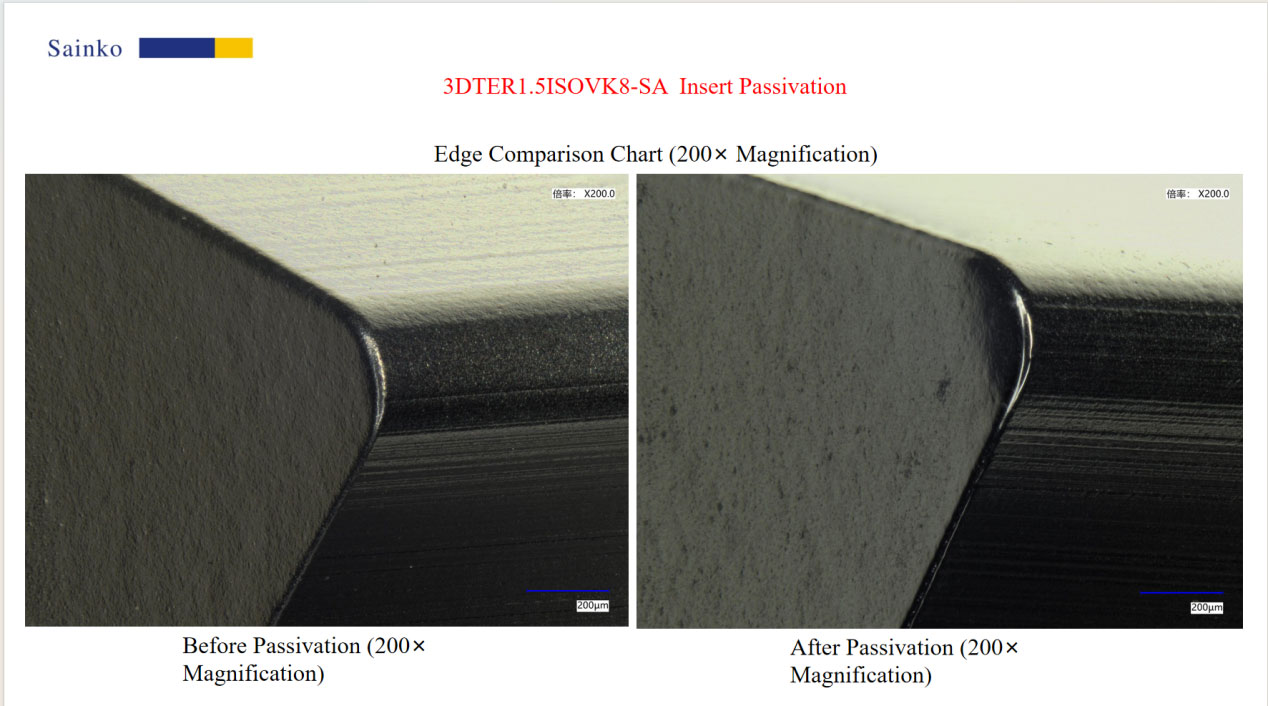

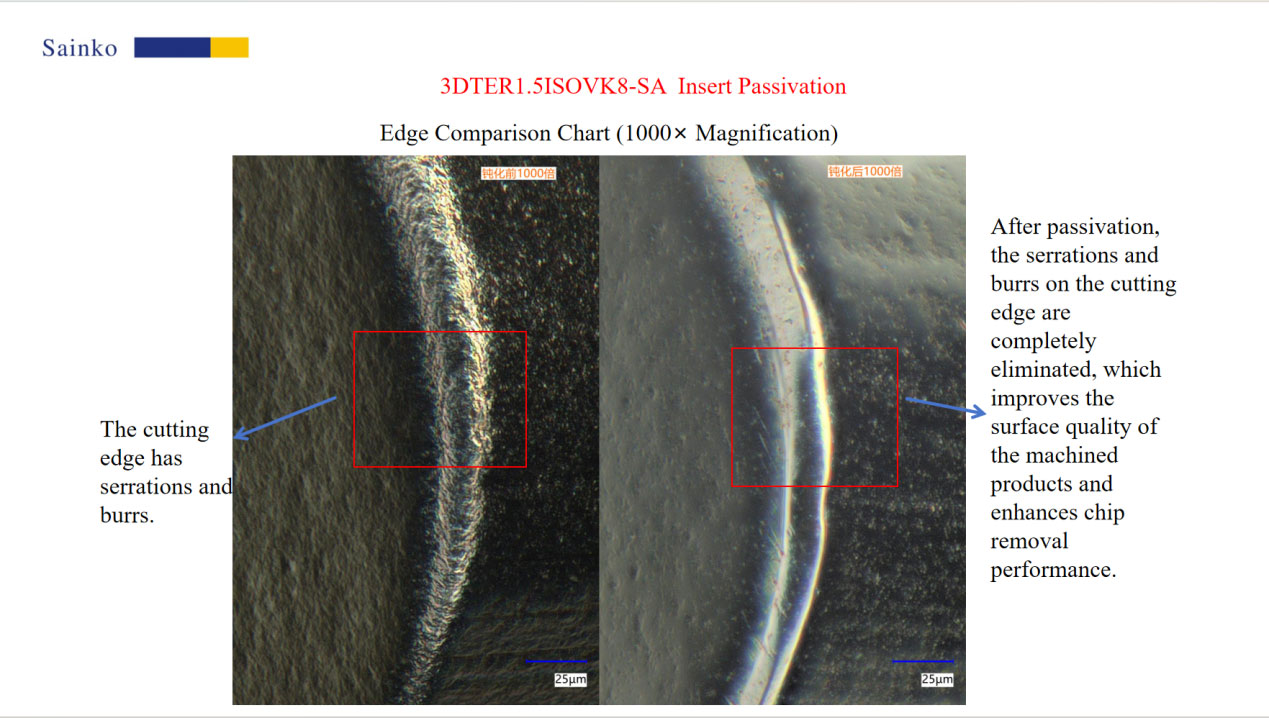

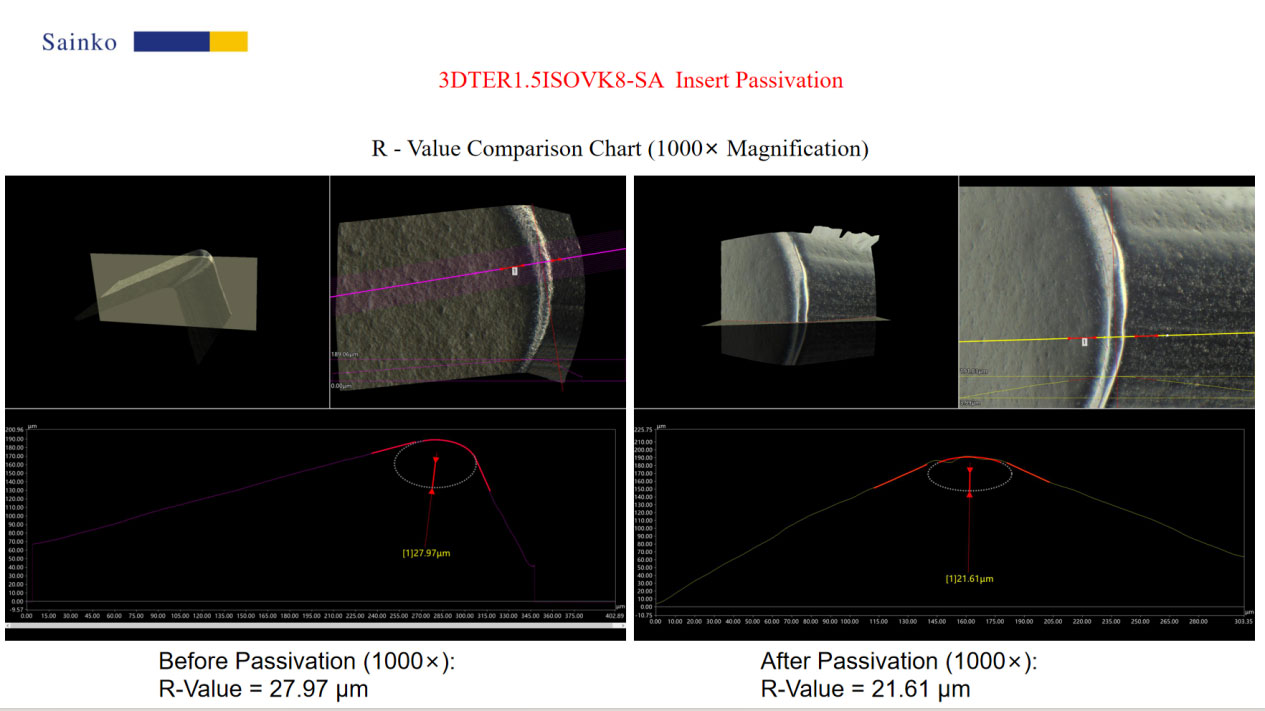

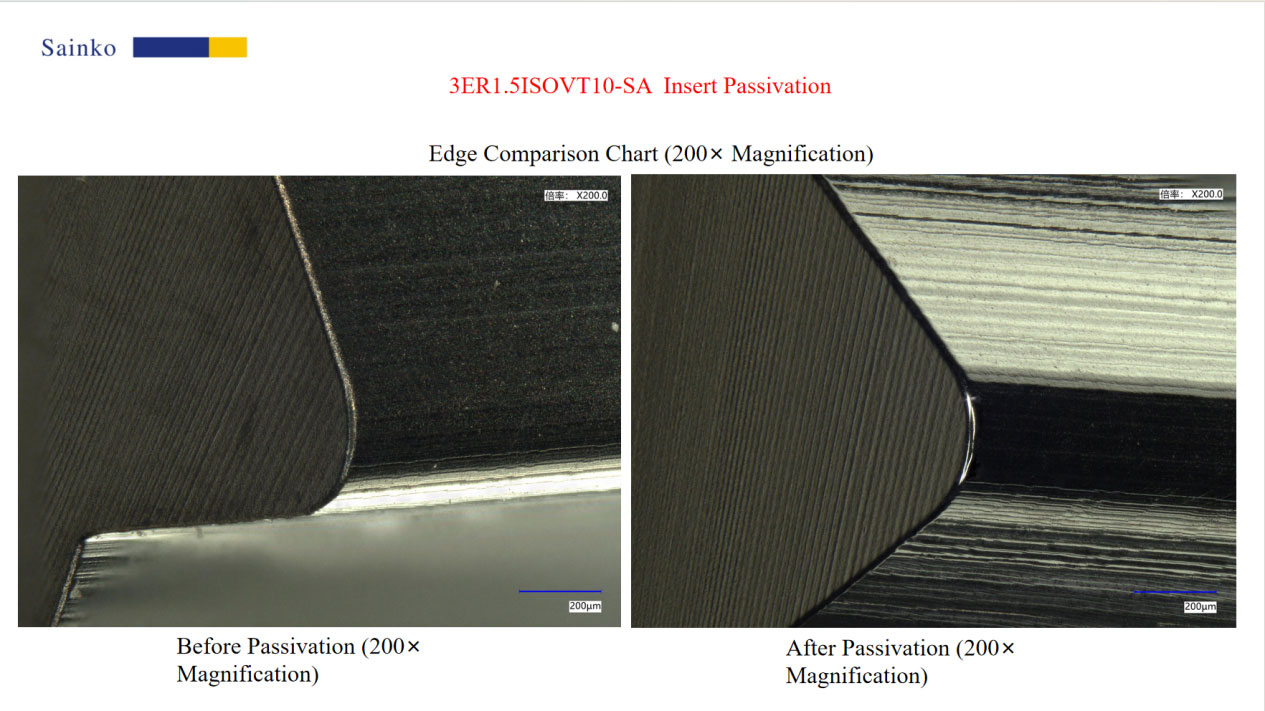

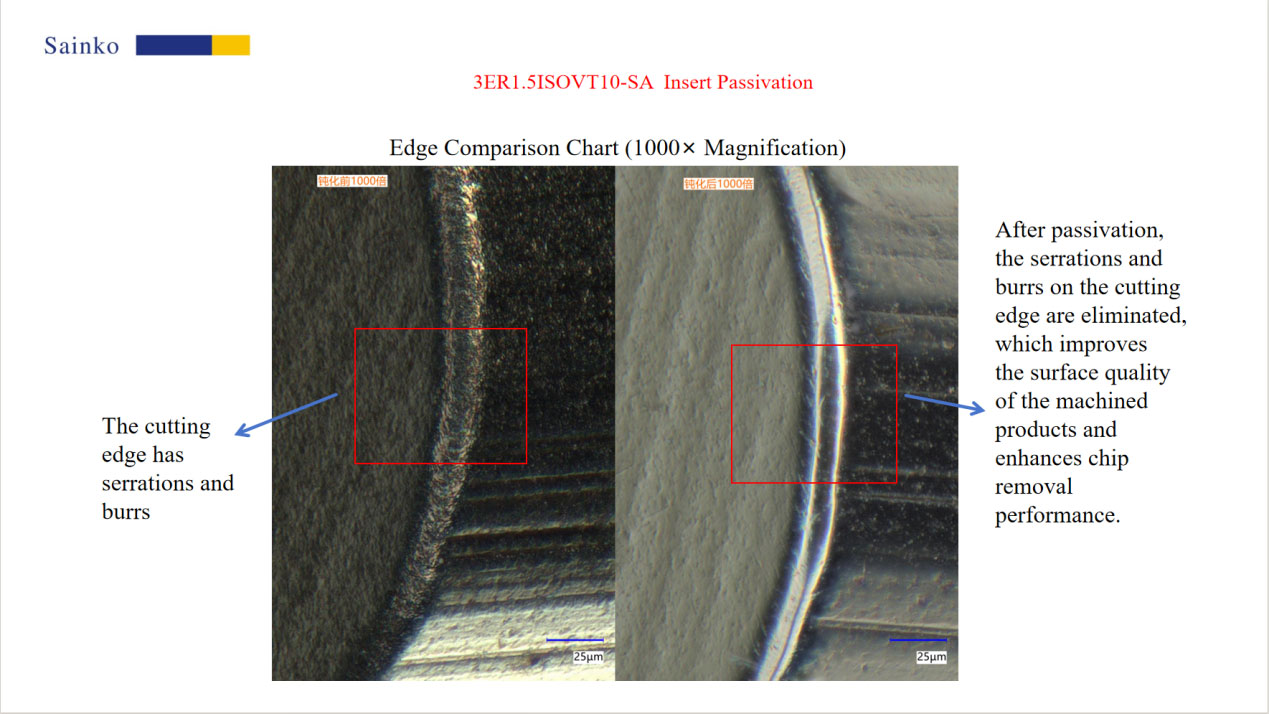

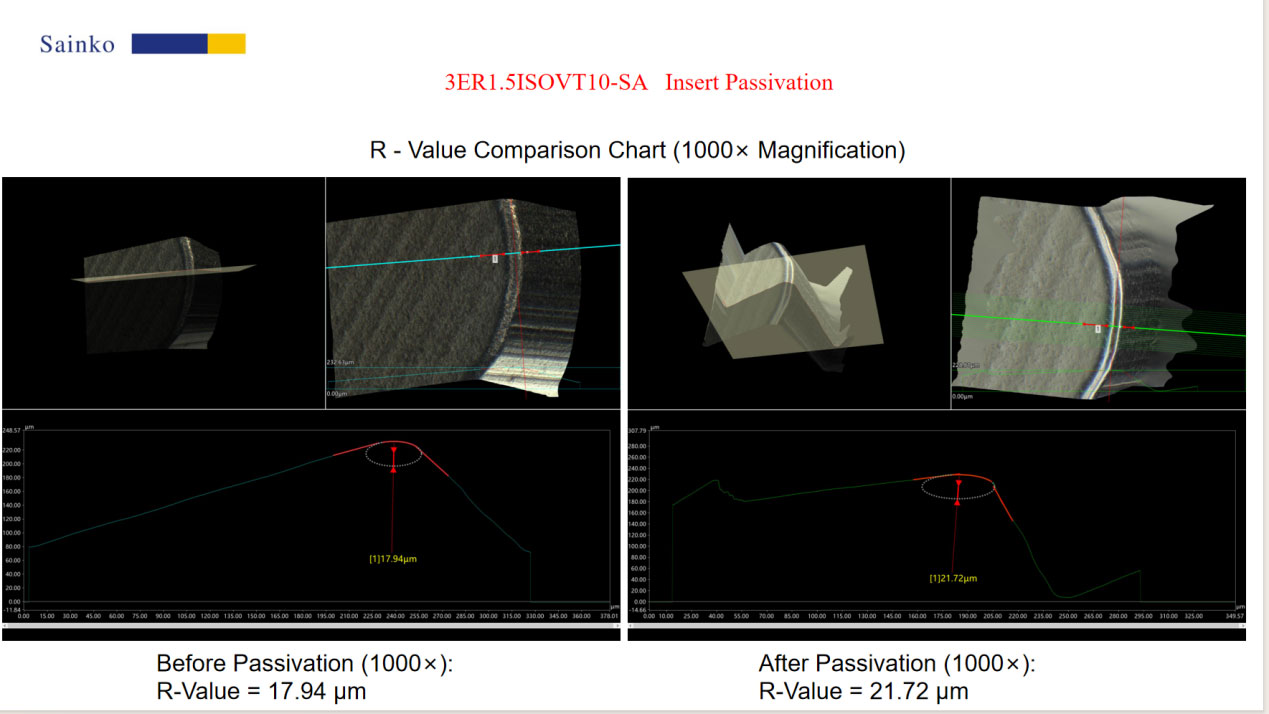

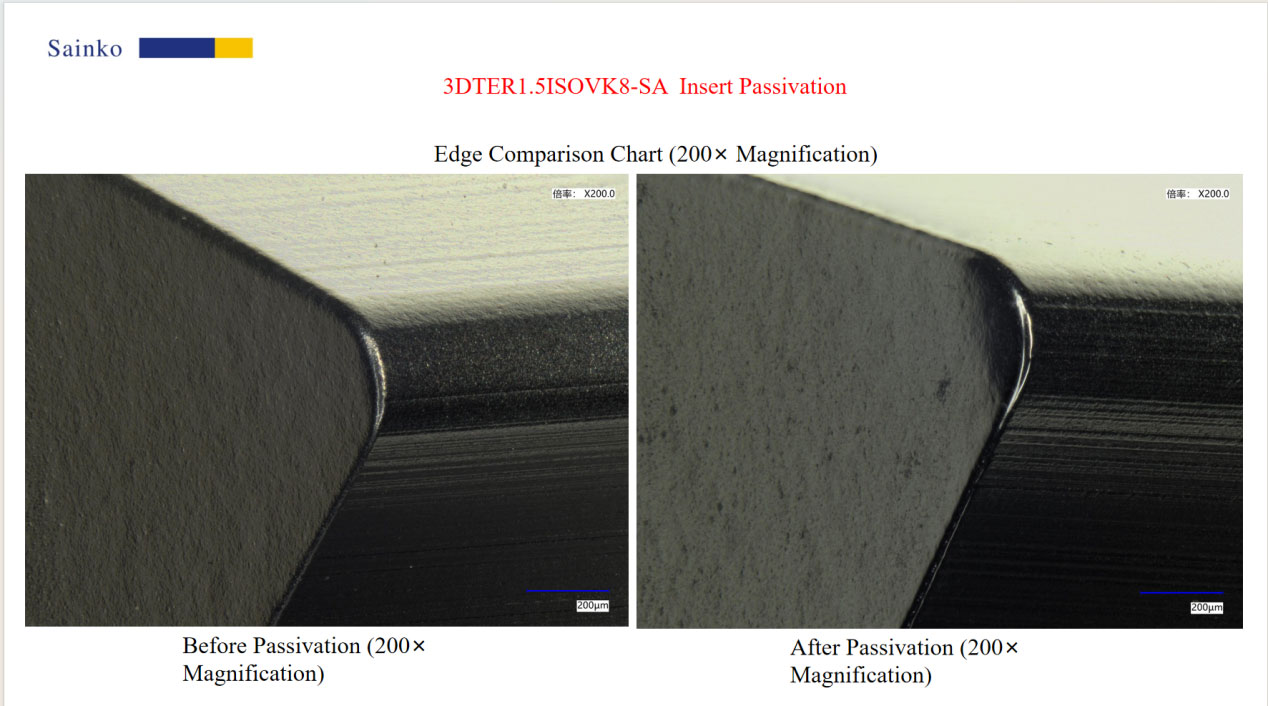

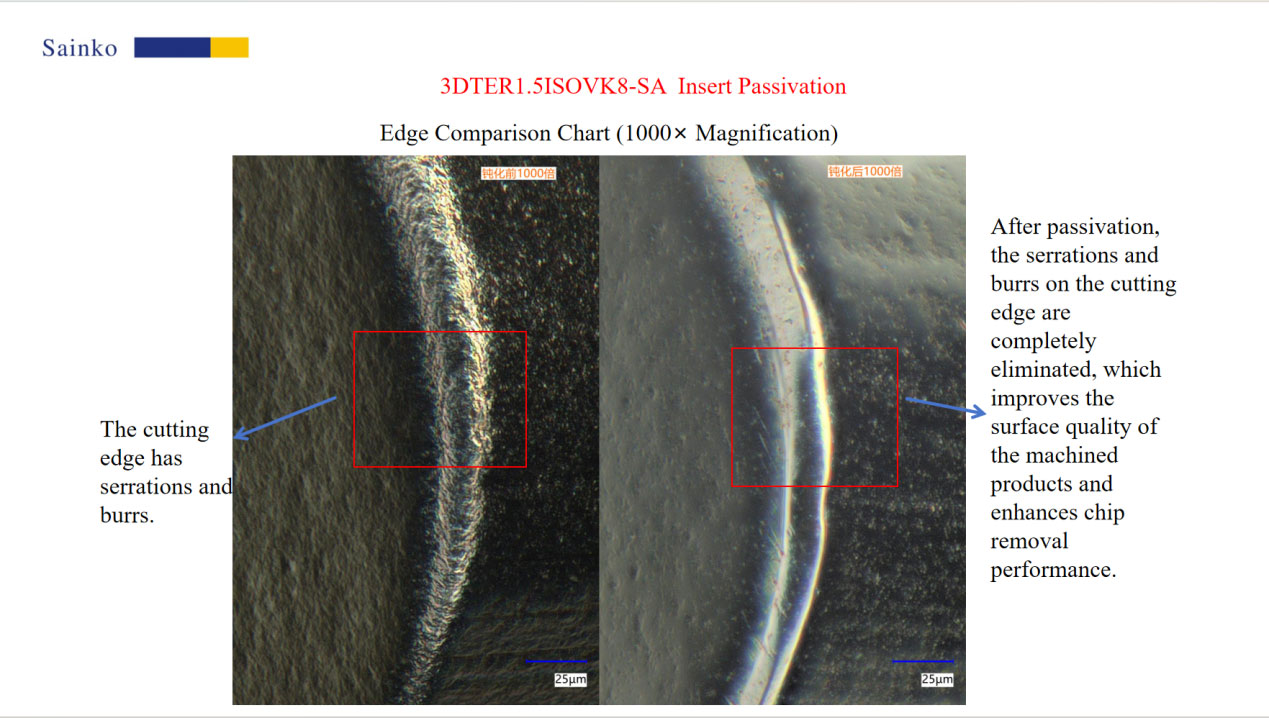

Verification was carried out via Keyence measuring equipment and microscopic observation at 200× and 1000× magnification, with significant results:

-

Before passivation, both inserts exhibited obvious defects such as serrations and burrs on the cutting edges. The edge radius (R-value) was 17.94 μm for one insert and 27.97 μm for the other.

-

After passivation, serrations and burrs were greatly improved. The R-values were precisely adjusted to 21.72 μm and 21.61 μm, both meeting the customer’s preset targets.

Subsequent application verification showed that the passivated inserts not only effectively improved the surface quality of machined parts but also optimized chip evacuation performance, providing reliable support for efficient and stable cutting operations.

2026-01-04

2026-01-04