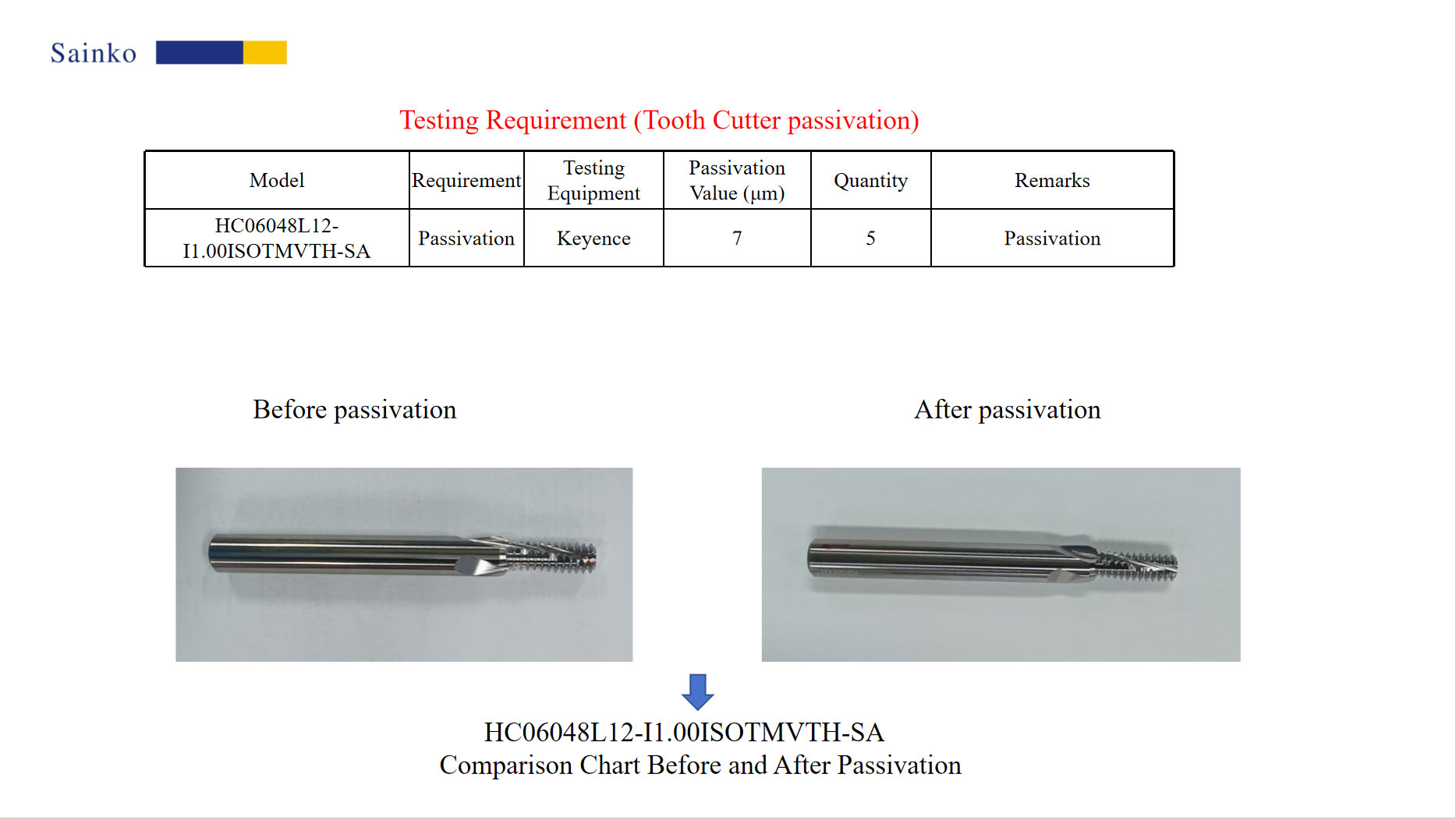

Samples: 5 pcs end mills provided by customer

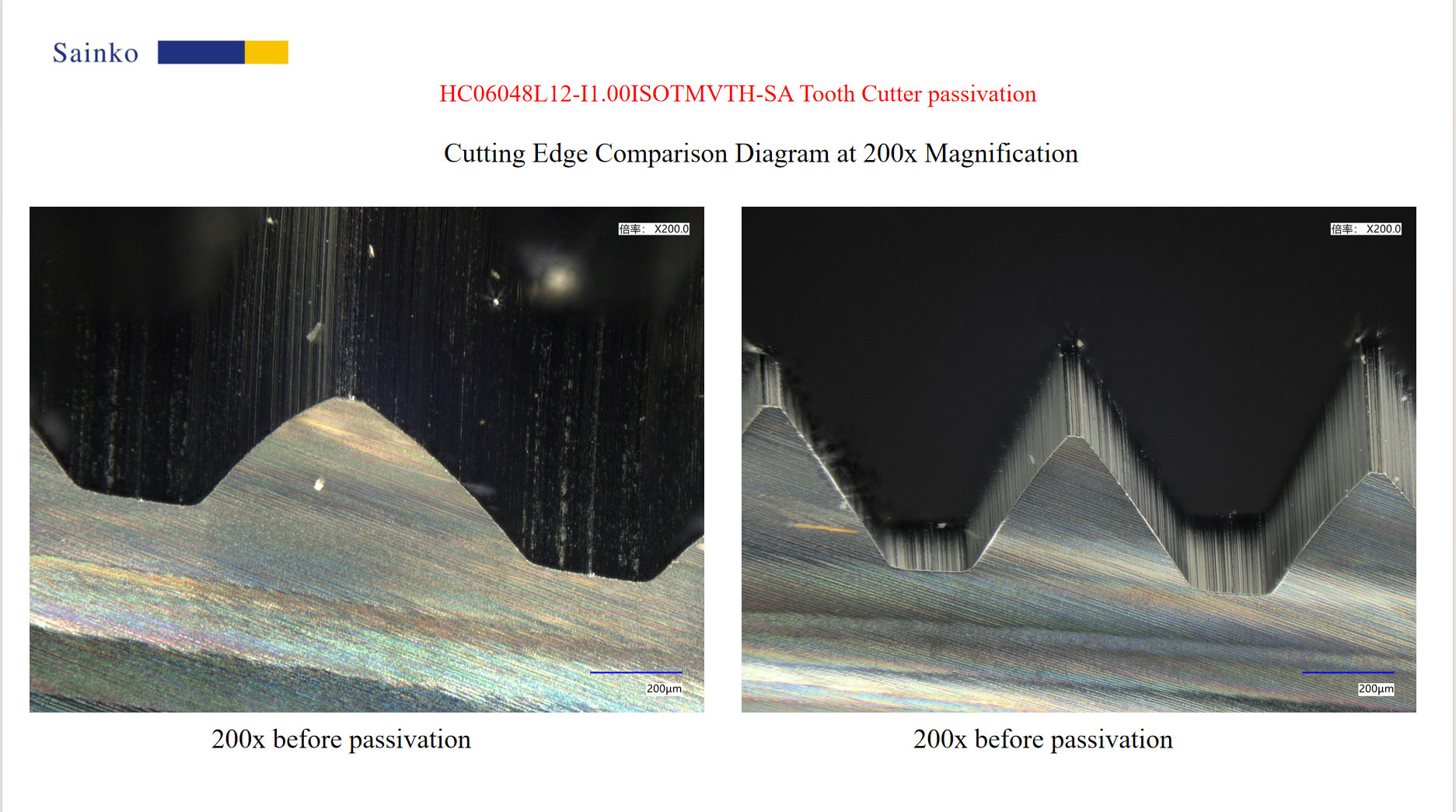

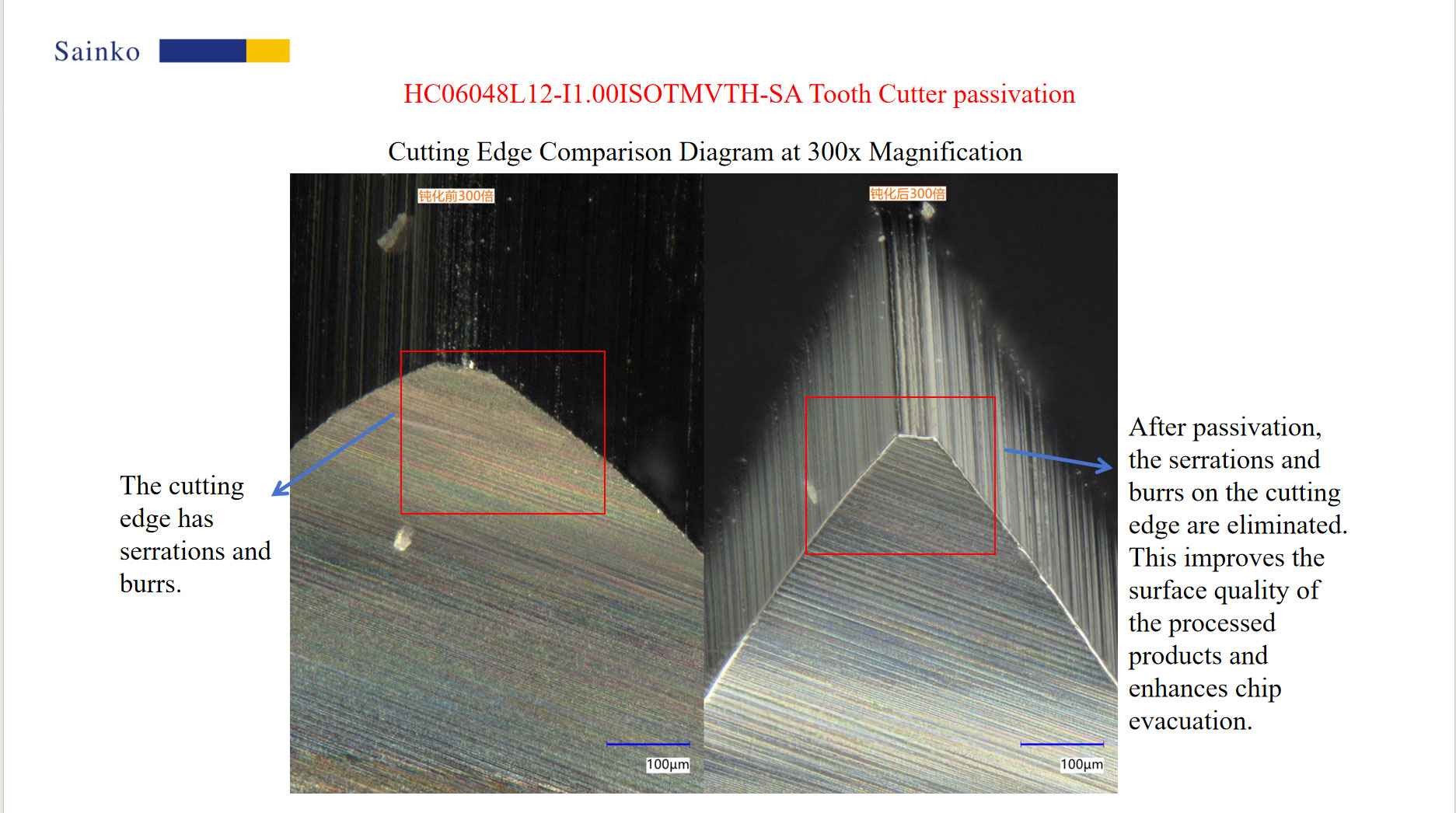

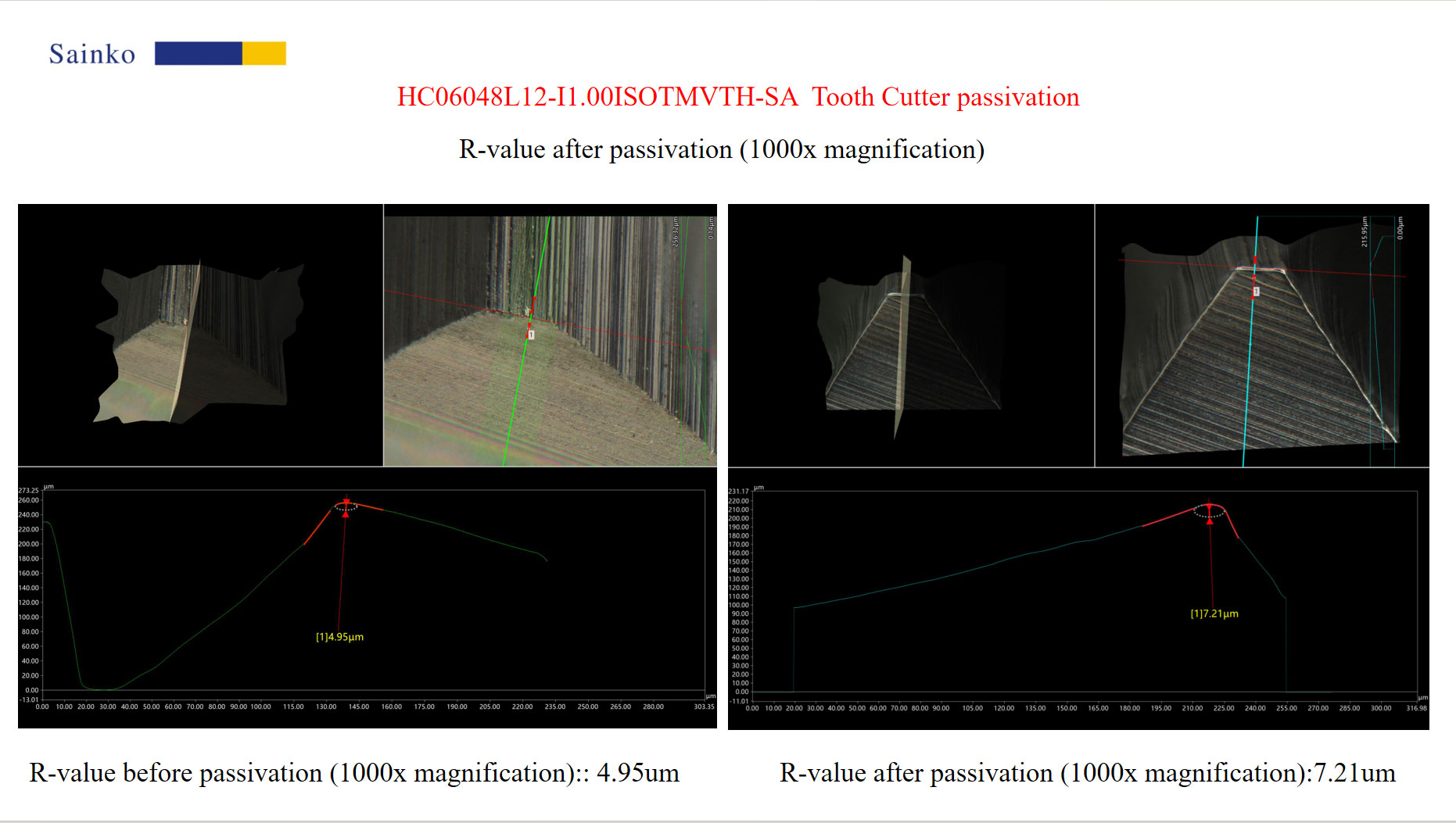

Requirement: Cutting edge passivation, target edge radius

7 μm

Equipment & Abrasive:

PL-24AX passivation & polishing machine with

15000-L abrasive

Process: Precise parameter control +

two‑stage blasting for uniform edge treatment

2025-11-24

2025-11-24